FEATURE ON KENCAST BY KENNAMETAL

By: Scott Bahr

In June, we introduced you to KenCast by Kennametal and some of its many uses. Today, we thought it was important to take another look at the versatility of KenCast and some of the specific benefits of the wear-resistant material. Thanks to a combination of steel and carbide, KenCast offers up to six times longer wear.

Photo courtesy of Kennametal KenCast catalogue.

KenCast works by blending various sized tungsten carbide particles to create the right combination of carbide protection. The tungsten carbide particles are then metallurgically bonded within an air hardened steel matrix which makes welding of KenCast to the component requiring protection possible. This process allows for easy placement on the mechanical component by site personnel or in a service shop.

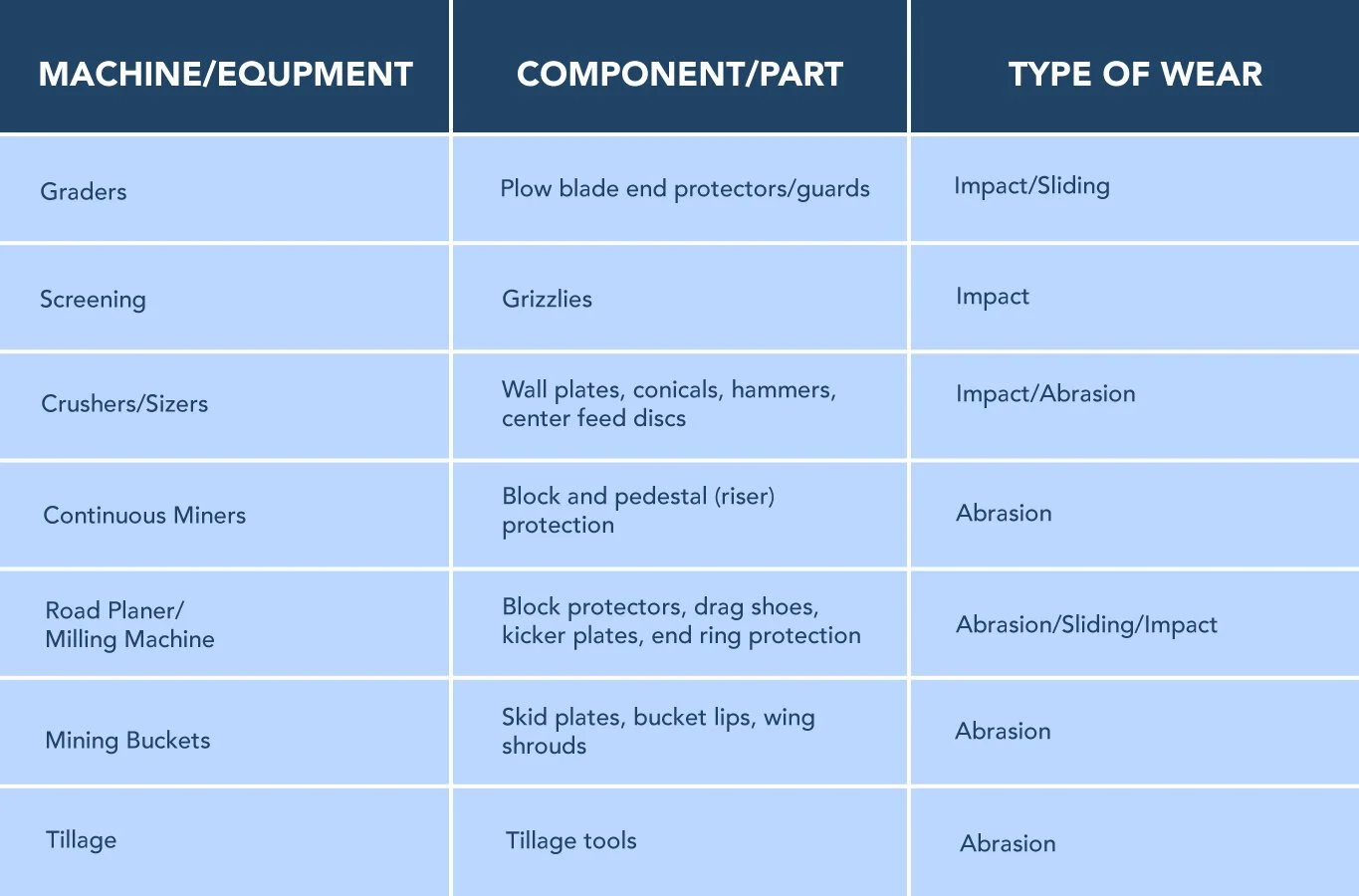

Some examples of how KenCast can be used to protect against the respective types of wear:

KENCAST TECHNICAL INFORMATION

Hardness:

• Tungsten Carbide = 86 to 91 Rc

• Matrix Steel (bonded to carbide) = 52 to 58 Rc

• Base steel = 38 to 50 Rc

Typical carbide particle size and where it is typically used in KenCast applications:

KenCast wear parts are proven to withstand extreme abrasive and high-impact applications and are easily welded or attached mechanically into the ideal position. If you’re looking for wear protection for your equipment, contact us at Bit Service to chat about KenCast and Kennametal–we’re proud to be an exclusive distributor in Canada. In the meantime, if you would like to do more research, this Kennametal KenCast catalogue goes into even more of the technical details of KenCast.