Industries

Bit Service provides products for mining, underground tunneling and more.

Mining

At Bit Service, we have been leaders in mining innovation for nearly six decades, serving Western Canada and global mining operations with cutting-edge solutions. Specializing in the design, fabrication, and repair of underground mining tools and assemblies, we tackle the industry’s toughest challenges head-on. Our mission is to optimize cutting performance and minimize wear, ensuring your mining operations are efficient, reliable, and built to last.

Featured Mining Products

Carbide Tools

With Kennametal’s leading-edge products from carbide tipped cutter bits and holders to...

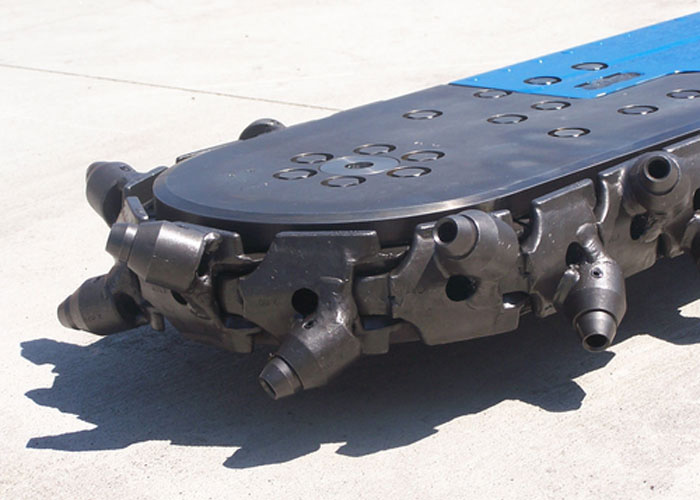

Cutterbars and Chains

Cutterbar assemblies for production and rehabilitation undercutters. Heavy-duty Roller Bearing Cutter Heads...

Explore our entire line of mining products.

At Bit Service, we provide a full suite of specialized tools and solutions designed to meet the unique demands of underground mining operations. Our product line includes cutting tools, wear-resistant assemblies, and advanced repair services, all engineered for maximum durability and efficiency in the toughest conditions.

In addition to cutting systems, we bring extensive expertise in bulk material handling to optimize your operations. Our services include analyzing existing belt conveyor systems to assess reliability and identify efficiency enhancements. We also focus on controlling and eliminating material spillage while designing innovative conveyor systems tailored to your specific needs.

Explore our mining products and solutions to discover how we can help streamline your operations and reduce downtime.

Underground Tunneling

The Canadian trenchless tunneling industry is a broad sector encompassing civil transportation, utility and ground water control applications. Large diameter TBM led alignments with segmented concrete liners through high precision tunnels mechanically cut with roadheaders are underway at all times across the nation. This demanding industry maintains the highest level of productivity and safety from itself and its supply chain, and we are here to answer the call.

Featured Underground Tunneling Products

Roof Bits

Bit Service provides precision-engineered, high-performance carbide roof bits for the underground drilling...

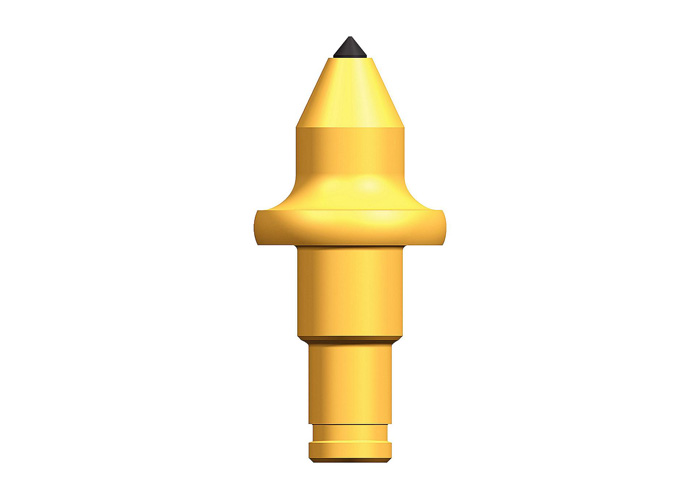

Conical Bits

Bit Service provides precision-engineered, high-performance carbide tools for the underground continuous miner...

Conical bits for trim chains and roadheaders

Explore our line of underground tunneling products.

Bit Service has a strong history supporting the Canadian tunneling sector, focusing on belt conveyor spillage control, mechanical cutting tools and wear reduction products.

Maintaining efficient and highly productive tunneling alignment through eliminating material spillage and adhesion on the conveyor system allows the tunneling equipment and crew to stay focused on increased meters of mining.

Fabrication

We’re not just a distributor – we manufacture products for the mining industry.

Being centrally located in the heart of mining country in Saskatchewan, we can quickly produce mining products at our manufacturing facility in Saskatoon and have these parts on-site in a matter of days.

Leaders in quality and reliability since 1965.

For over a half-century, Bit Service has been crafting cutting-edge tools for underground mining.

Our expertise now extends to full design, fabrication and repair of cutting assemblies for underground mining and tunnelling equipment, including cutting optimization and wear reduction.